There are a few reasons why having on board air makes sense with a truck, truck camper, off road rig, etc. The biggest time suck is returning from dirt to pavement and having to air up 4 large tires and it takes FOREVER. We’ve been there. Airing up tire for an hour. With all 8 tires in the image below needing air, it took quite a bit of time.

If this upgrade works, it’ll mean not ever choosing to air down for a more comfortable ride. Now, we can deflate the tires more often for those bumpy, rocky, off road adventures. Is it a success? Watch and see.

We had airbags when hauling this Lance camper on the same F350. We continued to use the same on board air compressor (mounted under the hood) to air up and down those air bags depending on the road condition.

Since then, we integrated Maximus onto the F350, removed those air bags and added an air horn to the truck.

For us the primary need for on board air is tire inflation plus our air horn. Other trucks may also have air jacks or air bags like we did.

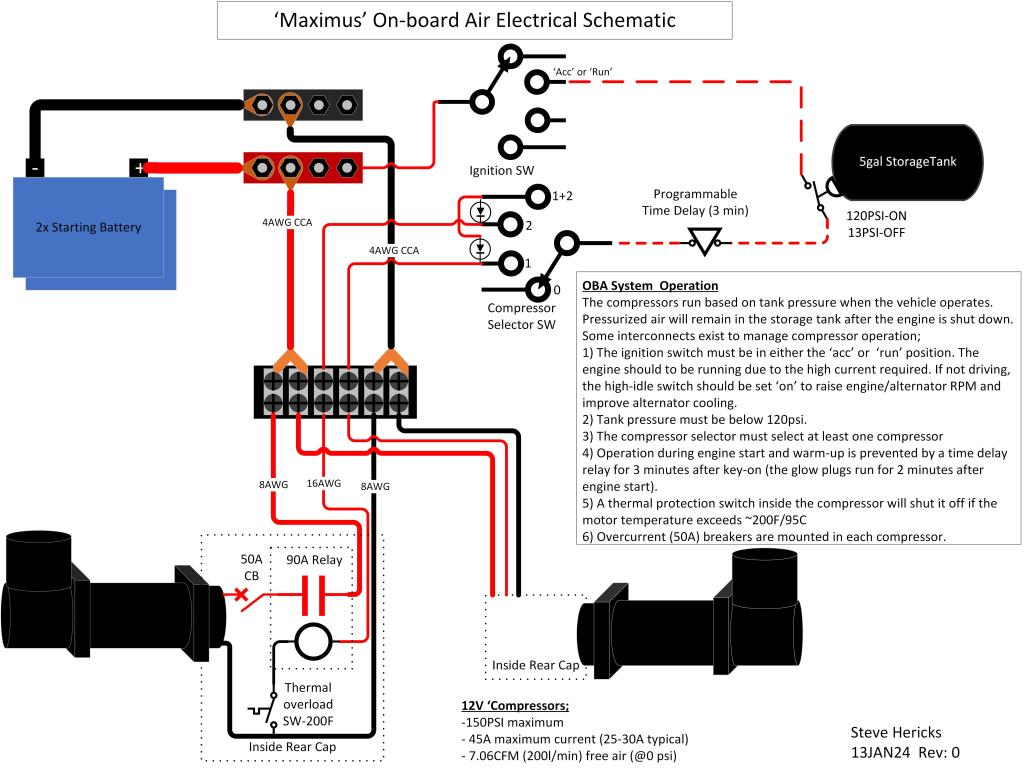

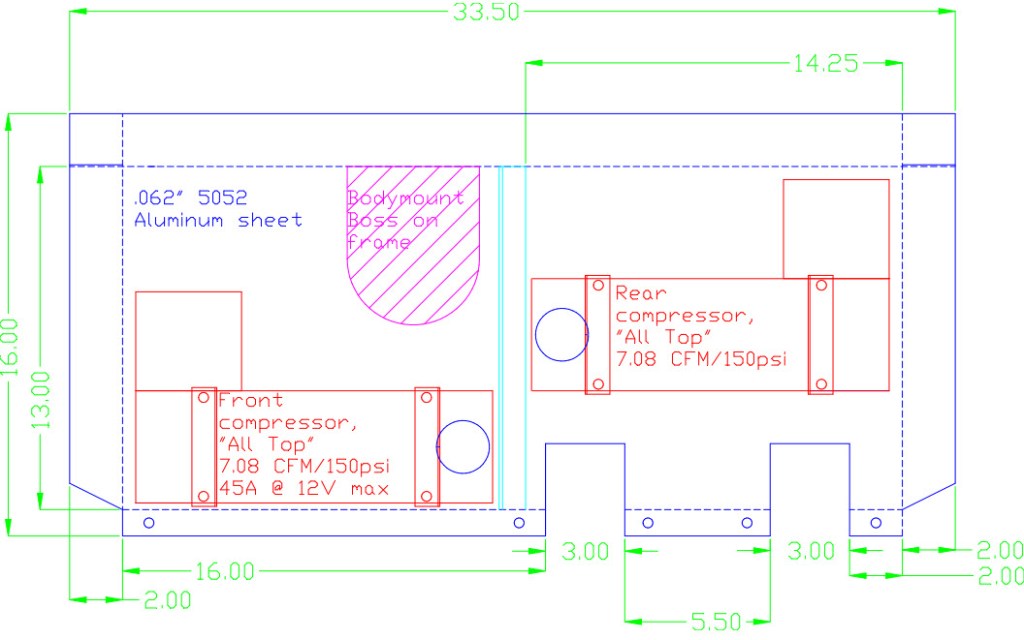

For this upgrade, Steve needed to think outside the box and devise a way to add extra capacity and redundancy. Then, he had to find a place in or on the truck to carry the system “on board.” Schematic can be downloaded by clicking the image below or visit our TechDocs Page for the download links.

Video

If you enjoy hitting the dirt but not your head on the roof liner, watch this and see how adding sufficient on board air can improve your off road bumpy adventures. Or add that air horn you’ve been wanting.

Related Posts

Missed our Biggest 2023 Adventure?

If you missed our 1st post of 2024 you check it out now.

A CO2 bottle and regulator is both cheaper and lighter.

LikeLike

Not a good choice for me; 1) a 20lb bottle weights 45lbs full compared to the 58lbs of hardware so not much lighter, 2) Filling all 4 tires requires evolving a lot of liquid CO2 into gas can end up freezing the regulator and damaging it (done that). 3) The tank has to be kept handy but is probably stored lying down on the floor in the back seat with stuff piled on top. It has to be set upright AND with air around it to warm it when in use, meaning unpacking the back seat so it can be taken out and then repacking it when done. That is really undesirable. 4) The unused space I put my compressors and tank in wasn’t able to be used for anything else so this would be an additional effort and a net loss of cargo space. 5) My last tank cost $28 for CO2 and $35 for the 5 year hydrostatic test so not cheap. Not only the cost, but the time and effort to get it filled. Takes me an hour and a half in SoCal and 3 hours in Idaho. 6) I use air for an air horn,. It would be possible to use CO2 but would require the tank to be stored upright and left on. I also use air to operate the tow brake in my jeep. If I were to use CO2, I would be needing to refill in unfamiliar places and much more regularly ($$). The compressor upgrade never mentioned this but it was a big factor in the decision. 7) The primary objective was to enable more frequent and larger volumes of air for both airing down AND using the tow brake. If I were adding all the cost and time into CO2 refills, that would reduce the likelihood of doing either. 8) Using compressed air for blowing out things on the road is also desirable and the cost and difficulty of using CO2 would prevent that…….As you can see, CO2 does not work for me.

LikeLiked by 1 person