It’s not a simple answer but, in short, it’s closer to being cozy than it was last month and some of the lights are working!

We timed hitting our overnight freeze temps with finally being able to have wall insulation installed. With a “cozy” photo theme this week and getting some insulation in place it seemed like an opportunity to document our shouse build progress.

Having a cozy place to reside can conjur up all kinds of images from fuzzy slippers (which I am wearing) to warm throws and puppy snuggles. Cozy here at the build is simply PINK.

This is a major milestone in our shouse building journey – getting insulated. As the temperatures begin to dip, it has made a subtle comfort difference in the shop and house. Unfortunately, being just wall insulation, I’m not sure I’ll call it cozy just yet. We are simply one step closer to achieving comfort.

It’s a weird feeling in the house now. With more of the interior framing filled in for sound insulation, both sound and light are muted. It’s a little on the eerie side to not hear everything from one end to the other.

Progress Leading Up to Insulation Round 1

Here’s what’s been accomplished leading up to the insulation. My previous update simply had us in the middle of the big 3: plumbing, electrical, and HVAC. Steve finished the plumbing and got our rough-in inspection approved. Next was wrapping up electrical work in the house and the electrical rough-in was also approved. Last electrical big task was recently completed and we now have a 200A service box installed and connected underground to the house. After the electrical inspection for energizing the house was approved, Idaho Power came onsite to complete the meter transfer and tidy up the cabling on their end. That went way smoother than I would’ve predicted! It’s exciting to have the shouse officially electrified!

Somewhere near the end of plumbing and electrical, work to run HVAC ducting, coolant lines, power and thermostat wiring was started up. End of August arrived and Steve’s HVAC work was as completed as he could get without the attic equipment. Initially it was communicated that everything would be available at the end of August yet now no one can tell us when they will actually arrive.

Then we waited. And waited. And are still waiting.

Feeling stuck without the final HVAC equipment required for full approval, we went ahead and requested our first HVAC inspection. All of our inspectors have been great and our HVAC inspector was no different. The process was seam-less. This milestone also let us check off our framing inspection. Approximately 11 months after framing was completed, we hit that major milestone.

Unfortunately, we didn’t receive our full HVAC rough-in approval. The caveat was we could now continue work up to the ceiling; the attic would need to remain open. Without the attic HVAC units in place we could only move to wall insulation and drywall work continues to be stalled.

Cozy Insulation

Being cozy has a lot to do with temperature and insulation plays a crucial role in maintaining consistent indoor temperature. It acts as a barrier to slow down the heat flow, ensuring that our home will stay warm in the winter and cool in the summer. I had already prepped our headers with insulation foam boards and completed the air sealing window, door, receptacles and sheathing gaps. The crew took about 4 days to fill all our walls and now we’re one step closer to being cozy.

Just Keep Moving

As of this week we now have a timeframe on receiving the elusive fan coil units. In September the supplier agreed to ship in our heat pump and buffer tank (instead of waiting for everything to be ready). That helped get a couple big pieces in place.

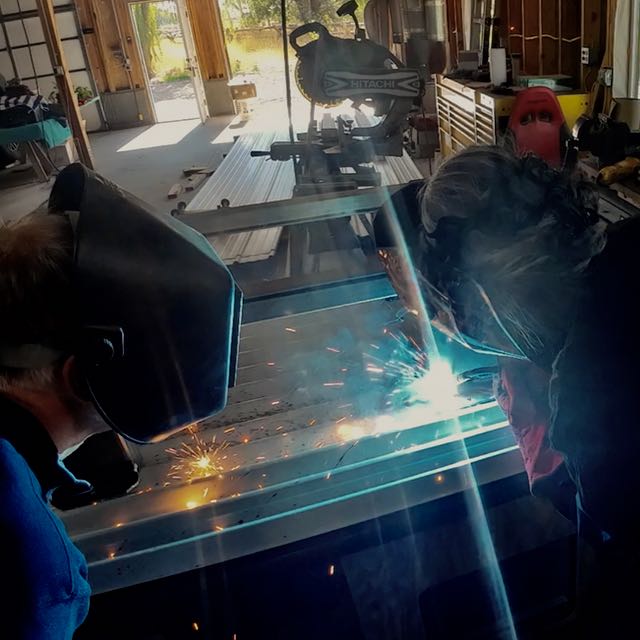

You know how candles can create a cozy ambiance? How about a welding torch?

Ok. Welding isn’t really cozy but with my great (and handsome) instructor, I finally got my first welding lesson. We needed a stand for the heat pump unit to be installed off the ground. What a great first timer project. It’s outside and will have limited exposure to critical eyes just in case I suck at welding. My steady hand enabled me to do well for a first timer.

After we finished welding the stand together, Steve painted it. Next it was ready to be leveled and bolted down. How would you lift a 400lb unit onto our new stand? Well we couldn’t do that without help and we found it in our trusty scissor lift and a couple ratchet straps!

Continue Progress Elsewhere

Although we really wanted to be dry walled in the house side and working on inside details like tiling, cabinets etc. we had to march forward with other areas and not be idle. Our other areas are the pool room and the shop.

We already had material on hand for the pool room ceiling, shop ceilings and shop walls. We started the pool ceiling and light installation then had to stop when we discovered one batch of lights would not fit into this surface mount t-bar. We’ll finish that up once the replacement lights arrive.

We also have our wall panels arriving next week and will jump on that as soon as work in the shop winds down.

The shop is getting some love now. We’ve had the ceiling panels for awhile and Steve’s made progress using his trusty assistant, the scissor lift. Once again, the scissor lift has been a great tool to have at our disposal.

Between equipment and our house cabinets in the shop, working in sections is the only way the shop can get its ceiling and walls done. Starting at the garage door end and working to the back is slow going. Ceiling panels followed by OSB on the walls, painting and some shelving, allowed Steve to start re-organizing the shop contents. That work is still in progress.

The shuffle of work benches and our house cabinet boxes continues this week.

Although full cozy hasn’t quite been achieved, we have made progress. Admittedly, we’re not happy about the delay getting us to a drywalled state but we keep plugging along where we can. Making progress is better than going backwards, no matter what the speed.

One nice improvement to our situation was getting our all-in-one washer dryer unit in place. Along with a decommissioned camper water heater we now have it sitting in the shop mechanical room. It’s a huge plus to have this appliance up and running for us and stop forking numerous quarters (estimated $30-$40 per month) to keep our clothes, towels and sheets clean. We love the efficiency of this unit; both power efficiency and labor efficiency.

Cozy Outside

If you made it to the end here’s a few more shouse and yard cozy views for you to enjoy:

About the Photo Challenge

A weekly themed photo challenge hosted by Terri. Check out her Blog and come back to visit for more SundayStills and traveling posts!

More Sunday Still Posts

Thanks for visiting our Retired Life & Travel blog and I hope you enjoyed finding the #SundayStills Challenge. You can join the weekly challenge by visiting our hosts blog Second Wind Leisure. and checking out Terri’s post for this week, A Cozy Refuge.

If you enjoy personal travel stories and especially camping, follow this blog by entering your email below. You can also follow us on Instagram @WorkingOnExploring or @Maximus.4×4.camper, and subscribe to our WorkingOnExploring YouTube Channel on for our build and trip clips. Good luck on your own exploring and we’ll see you from the road somewhere soon!

Follow WorkingOnExploring travels and ongoing #SundayStills photo Challenge Posts

Delivered directly to your email inbox.

This is looking amazing!! I love the look of the outside.

LikeLiked by 2 people

That is SO awesome to have so much done on your home, Cheryl! There are always delays, seems inevitable! But it sure looks more cozy in the before and after pics. Are you actually living there now? It will get COLD really fast (at least here in Eastern WA) this coming week. Hope you can stay cozy! The autumn pics look beautiful too! Talk soon!

LikeLiked by 1 person

We have the truck camper parked in the shop side and are still just living in the camper. Steve’s toyed with a way to heat up our floors this winter without depending on our missing HVAC equipment. The lines and manifold are in place. Just need a hot water source connected to them aka an electric hot water heater. He may still do that which will make working in the cold building easier for us and contractors. The camper is plenty warm and comfortable. Just small and confining when you can’t be outside as much this time of year…especially for a southern California gal.

LikeLiked by 1 person

Well, shoot, depending on how winter plays out, I’ll talk to you about maybe visiting you there on our return trip from Arizona. We’re leaving Dec 20 to drive to AZ and stay a few weeks like last year. We end up staying over night in Caldwell on both trips there and back.

LikeLike